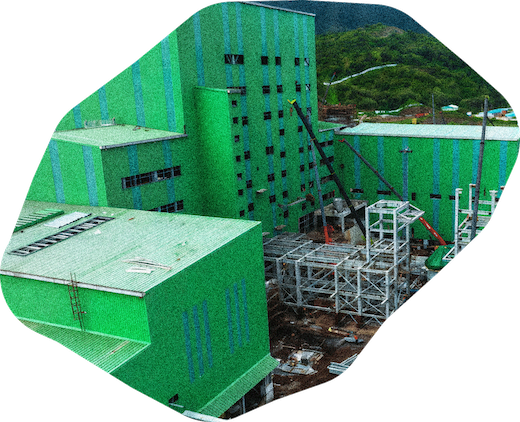

Main Feature of Our Copper Smelter

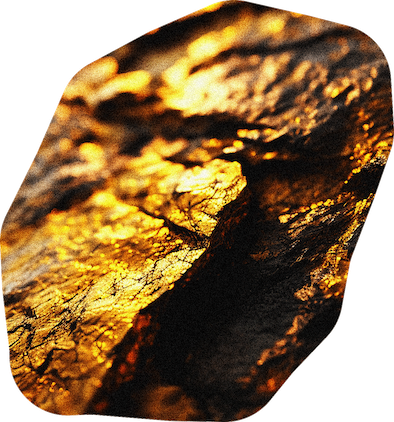

Smelter Feed

900,000 metric tons

of copper concentrate

from Batu Hijau and future Elang

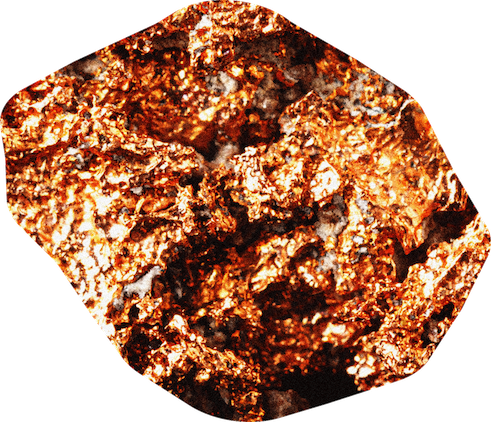

Smelter Product

220,000 metric tons

of LME Grade A copper cathode

with 99.99% purity

830,000 metric tons

of sulfuric acid

with 98.50% purity